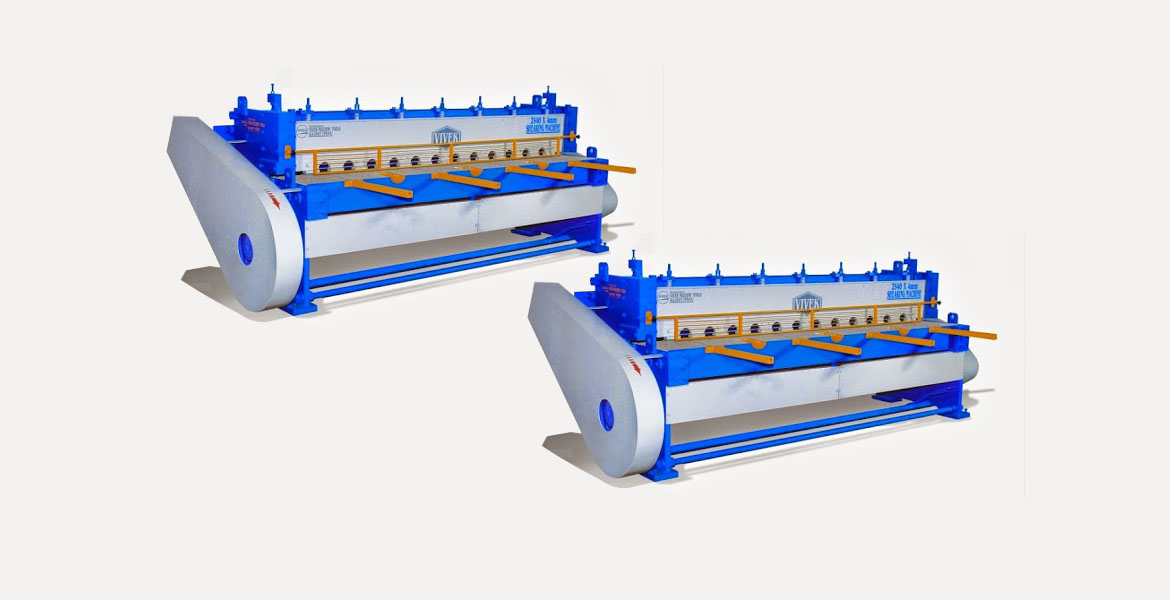

SHEARING MACHINE

We have earned a reputed position in the market by presenting top quality collection of Shearing Machine. These products are made by our experts using the sophisticated technique and optimum-class raw material that is procured from industry known vendors of market. Our products are highly praised in the market due to their features. Our experts can also modify these machines as per the needs of the customers.

UNDER CRANK SHEARING

SHEARING SIZES

shearing are available in capacities (size)of 4feet/5/6/8/10/12 feet &13 feet length thickness of machine is 0.100 mm up to 4mm capacities , rolling key clutch spring loaded mechanical hold down pads, increased productivity & reliability.

FRAME

The Body Frame is rigid steel constructed from Steel Plates with Safeguards steel plates designed for maximum Rigidity to Eliminate deflection and to Withstand continuous high Speed Performance at Full capacity.

MECH.HOLD DOWN SYSTEM

Mechanical Back Gauge is operated by Rack Pinion arrangement for easy and accurate cutting operations. The Front gauge moves on a "T" slot provided on the table.

BLADES (KNIVES):

Shearing’s are provided with high Quality single segment (one piece blade) AISI HCHCR d2 grade knives for longer tool life. Knives are precisely ground with perfectly sharp and Honed Cutting Edge. Providing long intervals between re-sharpening. The knife Blades are four Edged.

CLUTCH AND BRAKE

rolling key type Clutch is manufactured from WPS material Duly heat Treated To Provide long trouble Free Services. Spring operated Powerful heavy duty brakes is of release type works According to timing adjustment to Provide longer life to the brake.

Back Gauge:

this is standard mechanical equipment provided on all the shearing machine. Scale on the back gauge gives instantaneous reading of distance between shear and back gauge. Each machine provided steel fabricated screw type mechanical back gauge.

FINGER GUARD

To …avoid ….the…accident, Finger Guard is fitted in front of Hold down system for operator's protection without obstructing his view.

STANDARD ACCESSORIES

Gear & Wheel Guard, Hand operated back Gauge, Manual Lubrication pump, Stroke counter, T-Slot front supporters, front Scale gauge.

LUBRICATION

All moving parts are provided lubrication by hand operated pump for smooth operation.

| MODEL | CUTTING CAP. IN (MS) L. x THK. | STROKE PER MINUTE | TABLE HEIGHT | TABLE WIDTH | FRONT GAUGE | REAR GAUGE | MOTOR H.P./K.W. | BLADE LENGTH WIDTH X THICK | OVERALL DIM. IN MM. | ||

| L. | W. | H. | |||||||||

| VUS - 1 | 1270X2 | 55 | 800 | 400 | 600 | 750 | 2/1.5 | 1270X50X14 | 2100 | 1900 | 1300 |

| VUS - 2 | 1525X2 | 55 | 800 | 400 | 600 | 750 | 3/2.2 | 1525X50X14 | 2360 | 1900 | 1300 |

| VUS - 3 | 2030X2 | 55 | 800 | 400 | 600 | 750 | 5/3.7 | 2030X50X14 | 2825 | 1900 | 1300 |

| VUS - 4 | 2540X2 | 55 | 800 | 400 | 600 | 750 | 5/3.7 | 2540X50X14 | 3325 | 1900 | 1300 |

| VUS - 5 | 3125X2 | 55 | 800 | 400 | 600 | 750 | 7.5/5.6 | 3125X50X14 | 3910 | 1900 | 1300 |

| VUS - 6 | 1270X4 | 50 | 800 | 400 | 600 | 750 | 5/3.7 | 1270X63X18 | 2300 | 2000 | 1350 |

| VUS - 7 | 1525X4 | 50 | 800 | 400 | 600 | 750 | 5/3.7 | 1525X63X18 | 2550 | 2000 | 1350 |

| VUS - 8 | 2030X4 | 50 | 800 | 400 | 600 | 750 | 7.5/5.6 | 2030X63X18 | 3100 | 2000 | 1350 |

| VUS - 9 | 2540X4 | 50 | 800 | 400 | 600 | 750 | 7.5/5.6 | 2540X63X18 | 3600 | 2000 | 1350 |

| VUS - 10 | 3125X4 | 50 | 800 | 400 | 600 | 750 | 10/7.7 | 3125X63X18 | 4200 | 2000 | 1350 |